Industrial automation is the practise of using mechanised technology to operate machines and other industrial equipment while minimising human involvement in decision-making and manual command processes.

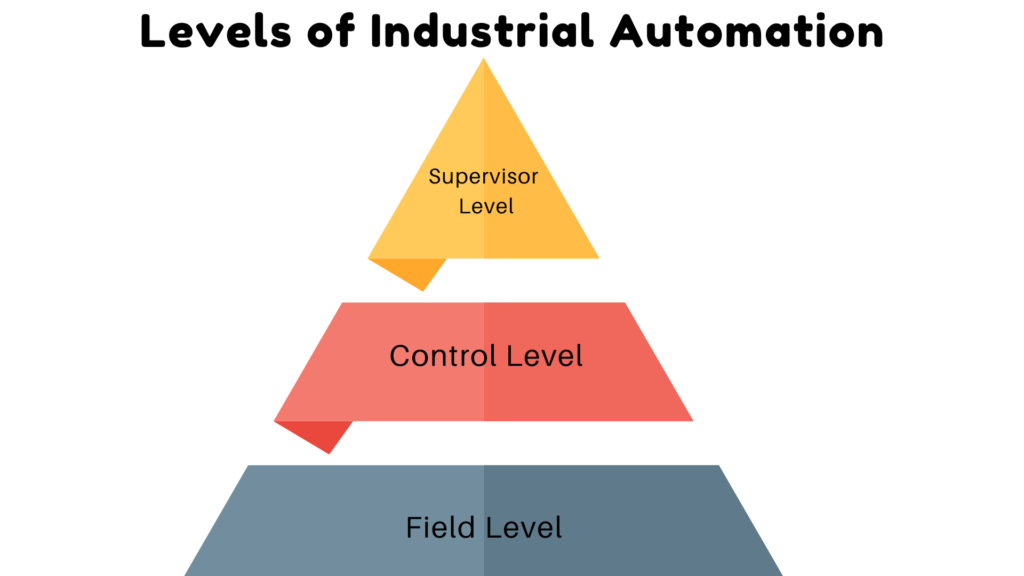

Industrial Automation Process Levels

The following hierarchical triangle of three-level representation of a typical Industrial Automation Application is the simplest approach to describe the tiers of an Industrial Automation Process.

Supervisor Level

The supervisor level, which sits at the top of the hierarchy, often consists of an Industrial PC, which is typically offered as a desktop PC, a Panel PC, or a Rack-mounted PC. These PCs utilise regular operating systems and specialised software for industrial process control, which is often supplied by the supplier.

The software’s primary goals are process parameterization and visualisation. For communication, a specialised industrial ethernet is utilised, which might be Gigabit LAN or any wireless topology (WLAN).

Control Level

All automation-related programmes are run at the Control Level, which is the middle level in the hierarchy. Typically, Programmable Logic Controllers, often known as PLCs, which offer real-time computing capacity, are utilised for this purpose.

To satisfy the real-time demands, PLCs are often designed utilising 16-bit or 32-bit microcontrollers and run on a proprietary operating system. PLCs can also interact with a variety of I/O devices and communicate via several communication protocols, such as CAN.

Field Level

In the hierarchy, the terminal equipment, such as sensors and actuators, is grouped under field level. The communication between a Field Level device and its related PLC is often based on a point-to-point connection.

Sensors like temperature, optical, pressure, etc. and actuators like motors, valves, switches, etc. are interfaced to a PLC through a field bus.

The PLC can diagnose and parameterize numerous components through this connectivity, which utilises both wired and wireless networks.

Systems Needed :

A process system for industrial automation also needs two key systems. As follows:- Supply of Industrial Power

- Protection and Security

Varied systems at various levels of the hierarchy may have quite different power needs. For instance, large motors often operate on either 1-phase or 3-phase AC, while PLCs typically operate on 24V DC.

Conclusion :

Therefore, a variety of suitable input power supplies are needed for a smooth operation. The software that is used to operate the PLCs should also be secured because it is readily corrupted or updated.

ALSO READ

You may also like our other related articles on automation :