It can be pleasing to remain with what’s working when it comes to the supply chain for your company. There’s a significant probability that you still perform inventory calculations, selection, packaging, and other duties by hand if your business has been operating for a long.

But some traditional supply chain automation methods aren’t only obsolete; they’re also ineffective and could even be harmful to your business.

Modern technologies have made it possible for businesses to leverage automation in the supply chains. Supply chain automation may boost productivity, save you money & time, and position your company for future when used properly.

We’ll discuss supply chain automation in this post, as well as its benefits and drawbacks, and the procedures that are automated in your supply chain.

Supply Chain Automation: What Is It?

Supply chain automation means the use of technological solutions to carry out or speed up those activities without the involvement, attention, or labor of humans.

A corporation can reduce the amount of physical labor necessary to carry out specific business operations by integrating automation technology like machine learning, artificial intelligence, and digital process automation into the supply chain.

This quickens processes and improves the effectiveness of the supply chain.

Advantages Of Supply Chain Automation

Supply chain automation may benefit in a variety of ways from automation. Here are a few ways that automation can help supply chain.

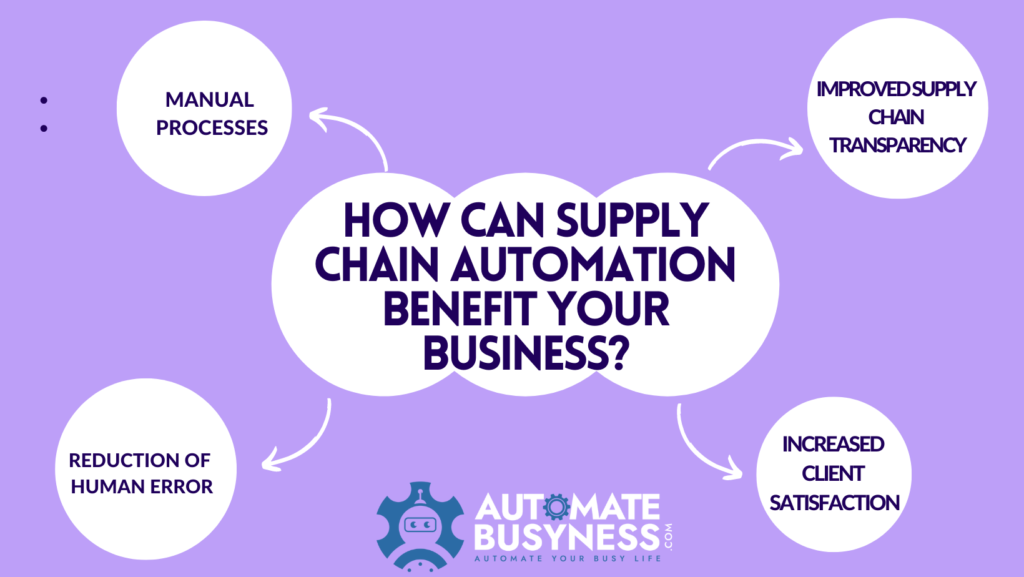

Automation Of Manual Processes

With the help of supply chain automation, your company may shift employees’ attention away from tedious, time-consuming duties and toward jobs that demand human interaction.

For instance, producing necessary documentation, processing orders, allocating choosing slots, and paying invoices can take a long time.

By automating these chores, you may assign them to technological answers that can finish them much more quickly, freeing up human workers to handle issues that genuinely require their involvement.

As a result, supply chain is more efficient because you aren’t wasting your employees’ time and talent on jobs that another party could do.

Reduction Of Human Error

When duties are carried out manually, it is quite possible that something will go inaccurate since humans make mistakes.

Automation reduces the chance of error by eliminating humans from the process, which can stop errors like:

By automating these chores, you may assign them to technological solutions that can finish them much more quickly, freeing up human workers to handle issues that genuinely require their involvement.

As a result, your supply chain is more efficient because you aren’t wasting your employees’ time and talent on jobs that another party could do.

Improved Supply Chain Transparency

It takes a ton of work, transmission, connectivity, and dedication from retailers, suppliers, and assistance providers to maintain supply chain visibility.

Information is automatically registered and modernized in almost real-time thanks to digital automation. This makes it possible for interested parties to track inventories, acquire crucial information as needed, and communicate rapidly across supply chain.

The efficiency of your supply chain will therefore rise as a result of the quick identification and elimination of bottlenecks that will stop additional delays and interruptions.

Increased Client Satisfaction

Your clients will gain from the streamlining of supply chain brought about by automation. A highly automated supply chain helps you keep increased customer satisfaction and loyalty momenta while promptly filling and shipping precise orders to clients.

Supply Chain Automation Has Its Limits

Even though automation has many advantages, you should be aware of some of its limitations. These restrictions might be especially noticeable in the supply chain of a small organization because there are rarer resources and less money available.

Confined At The Moment To Specific Duties

Not every aspect of the supply chain can be automated. The majority of Supply chain automation will still require human involvement and attention, even while relatively routine tasks like demand processing, stock counts, and managerial tasks are excellent prospects for automation.

For instance, even though picking lists can be generated automatically and warehouse robots can be assigned to help with the actual picking, these robots are even unable to make important decisions depending on the circumstances at hand (for example, what to do in case of shortages).

Additionally, they lack the mastery required to pick particular things that are kept in more difficult areas.

Cost

The cost of annual costs or one-time licences for advanced supply chain technologies can typically go into the hundreds of dollars.

Smaller ecommerce enterprises and newly launched DTC businesses would not be able to afford this kind of substantial financial commitment.

These firms typically outsource warehousing and fulfilment processes to a tech-enabled 3PL or logistics medium in order to gain access to supply chain automation tools.

What steps in the supply chain can be automated?

Despite the fact that it is presently not viable to automate complete supply chain, businesses might do so by automating certain crucial procedures and jobs. Here are a few supply chain procedures you could want to automate.

Back-Office

Automation of the supply chain greatly simplifies management of routine business operations and administrative responsibilities.

Your financing & accounting activities can be automated by processing invoices and keeping track of your finances, and some systems let you automatically pull data from purchase orders into your programme.

Automation has a positive impact on supply chain analytics as well because it frees up business owners’ time to focus on running their operations rather than monitoring critical performance indicators.

In this approach, supply chain automations can really give your company more precise information that can be used to enhance both present operations and future planning.

For instance, to enhance demand forecasting and procurement, predictive analytics automations including machine learning evaluate past inventory and sales data.

In contrast, cognitive analytics automations—programs that use machine learning and artificial intelligence to model human decision-making based on data sets—enable a more efficient, speedier decision-making process.

Transportation

You can use automation in a few of your transportation-related processes.

Automations for route-optimization select the optimal routes and carriers for goods, which can speed up delivery and cut shipping costs.

Numerous automation systems offer real-time transit tracking for improved supply chain visibility. This makes it possible for you to maintain a careful eye on the whereabouts of your cars, the inventory items that are in transit, and any potential delays.

The flow of your items can then be optimised using this data in order to save operational costs and travel times.

Warehouse

The two supply chain activities that use automation the most are fulfilment and warehousing.

Certain software automations can automatically receive and confirm orders, process orders, and send customers tracking information.

Depending on the circumstances, these programmes can also automatically route each order to the fulfilment centre that is located closest to the intended recipient.

Some warehouse automation solutions include goods-to-person (GTP), where machines and robots are used to support human workers in the warehouse picking process, when it comes time to pick orders.

Additionally, pick-to-light (PLT) systems, which use barcodes and LED lights, can increase how quickly employees find the proper goods to choose.

In order to reduce dimensional weight and lower the chance of damage, you can also utilise the box selection algorithm to make sure that each order is shipped out in the optimum package size.

To maximise storage space while improving picking productivity, some warehouse automation technologies even have capabilities that help you decide where to put your inventory the most effectively.

Inventory

While some portions of inventory management can be automated, it still requires human knowledge in many areas.

Automatic reorder point notifications help you time replenishment correctly and avoid stockouts and backorders when you reach a threshold number for a specific SKU.

In order to save time and hassle, some retailers decide to automate the entire restocking process and set up their system to automatically order stock if an SKU reaches its threshold.

The best visibility into inventory levels so that you know precisely how much product you have remaining at any one time comes from automatic inventory counts that are current, even to the minute.

ALSO READ

You may also like our other related articles on automation :