We live in a disruptive era when firms must quickly adapt to new changes.

The rising levels of demand are beyond the capacity of conventional supply chain management. The implementation of automation technologies is the key to attaining a competitive edge.

In this article, you’ll discover why data capture automation can help your organization become more competitive, as well as the reasons why supply chain automation has become essential.

What Is The Supply Chain Automation ?

A supply chain includes every step of the production and distribution of commodities, from the acquisition of raw materials to production, storage, distribution, delivery, and recovery. To remain competitive, you must make your supply chain as efficient as possible.

Supply chain automation is the use of contemporary technologies to automate formerly manual operations in order to improve workflows and productivity. Among these technologies are:

- robotics in storage

- Network of Things

- Machine intelligence

- computer learning

- predictive modeling

- Automatic digital processing

- Character Recognition Through Optics

- Automation of data entry.

Automation is both a need and a game-changer. Companies that continue to rely solely on legacy procedures will soon be unable to compete in a world that is changing quickly.

Processes From The Past Without Automation Are Old And Expensive

The typical supply chain has a linear path from suppliers to end users and relies on internal operations including document management.

However, the strategies that ensured earlier success are no longer as effective and will soon be wholly obsolete.

Demand-driven paradigms have already taken hold in the world, where customers place more orders more frequently, anticipate quick delivery, and have access to real-time data.

High demand levels are simply too much for legacy procedures to handle. They are also expensive and prone to mistakes.

Problems like lost or delayed goods may lead your clients to turn to a rival.

This is why continuing to use outdated procedures can prevent your company from expanding. Companies are adjusting to this reality in increasing numbers.

According to a Raconteur study, 41% of supply chain experts have purchased or want to purchase a supply chain management system within a year.

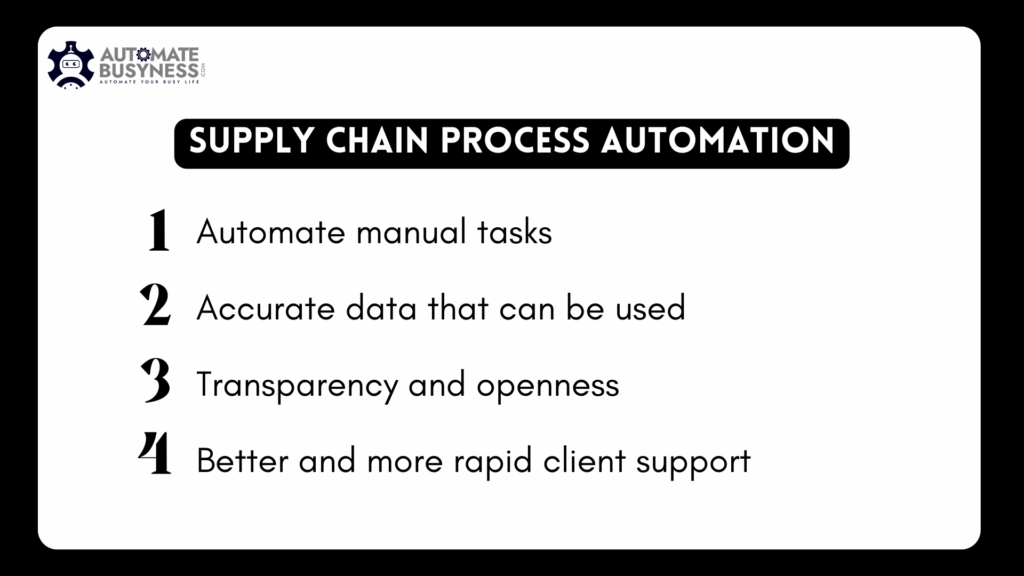

Why Supply Chain Process Automation Can Help Your Business Grow While Saving Money

Supply chain Automation can help your organization grow while also improving the effectiveness of your supply chain and lowering costs. As follows:

Automate Manual Tasks:

One of the supply chain tasks that take the most time is document processing. Even worse, bottlenecks might result. You may save a tonne of time and money while greatly improving the efficiency of supply chain automation is by manual processes.

Employees can also concentrate on more fruitful activities like prospecting and developing relationships with clients.

Accurate Data That Can Be Used:

Data silos are broken down and quick access to trustworthy data is ensured because to the interconnectedness of automated data.

Leaders can quickly create dynamic reports that are simple to distribute and make informed decisions, like demand planning, based on accurate data.

Transparency And Openness:

To prevent order and delivery errors, visibility enables workers from many departments and locations to stay on the same page.

Similar to how shipping automation promotes greater transparency, clients may track the status of their orders with the most recent data.

Better And More Rapid Client Support:

With reasonable prices and current order information, automation enables you to guarantee quick delivery times.

Customers are more demanding than ever, therefore it’s imperative to live up to and even above their expectations if you want to succeed in your industry.

It is clearly obvious which benefits automation brings to supply networks. But what really does automation entail? Let’s look at some of the automation methods that have the biggest effects.

Supply Chain Automation Types

Multiple types of automation exist. Some of the most extensively used automation technologies are listed below:

Automated Data Collection

Data automation may significantly improve corporate operations at a time when companies need to save costs wherever they can.

Due to the sheer volume of documents that must be processed every day, including invoices, inventory lists, purchase and sales orders, shipping notes, bills of lading, and others, data entry is one of the most time-consuming and error-prone operations in the whole supply chain.

Additionally, since there is a speed restriction on how quickly employees can type data manually, as time goes on, their ability to remain focused and productive would certainly decline.

Fortunately, data capture automation may use optical character recognition (OCR) and other comparable technologies to retrieve information from digital or scanned documents. With as many documents as you have, you can repeat this process in a matter of seconds.

Automation In The Warehouse

Due to the various advantages warehouse robotics provide, like higher efficiency and order accuracy, businesses are investing in them (55% of them, to be exact).

Because robots perform the actual heavy lifting, they also reduce workplace injuries caused by accidents or tiredness.

Collaborative robots, intelligent forklifts, automated storage and retrieval systems (AS/RS), autonomous cars, automated sortation systems, and other devices are all included in warehouse automation.

Internet Of Things 3. (IoT)

IoT devices have the ability to communicate data, track stored products, and report on their position and status. They are used by supply chain managers to minimise paperwork and track the movement of commodities.

They are especially helpful in the food and retail industries for tracking products that are susceptible to changes in temperature or humidity.

Despite the fact that IoT devices need wireless networks (WiFi, Bluetooth) and skilled personnel to function effectively, the potential ROI (optimising stocks, decreasing waste) makes the investment well worthwhile.

Analytical Modelling

While modern supply chain management takes a proactive stance, traditional supply chain management often takes a reactive stance while anticipating client requirements.

This is where predictive analytics comes in, by using data analysis to predict future trends. Demand forecasting, pricing strategy, and inventory management are just a few of the many applications for this risingly popular automation technology.

The Advantages of Supply Chain Data Automation

Did you know that data entry mistakes in the supply chain, procurement, and other areas cost firms about $600 billion annually?

Automating data collecting can help to a significant extent in resolving this inefficiency. It specifically enables you to:

Simplify The Data Collection Procedure:

Automation improves data quality and streamlines supply chain operations, reducing order errors and backlogs in invoicing.

Furthermore, you will be able to accept more business because to this enhanced processing capability.

Spend Less

Numerous man-hours spent inputting and validating data are saved via automation. Additionally, it reduces the risk of errors, their associated financial losses, and the expense of correcting them.

Minimise Human Error

The amount of data that needs to be processed increases along with the size of your firm, which eventually results in increased costs and errors. Even the most competent workers occasionally make blunders.

Automation promotes customer happiness and retention by minimising human error and maximising order accuracy when properly configured.

Get Data Access Made Simpler

You must scan, fax, or in certain situations have someone deliver paper papers to another place in order to share them.

However, exchanging data has never been so simple thanks to the digitization of papers, which helps everyone involved save a tonne of time and work.

The fact that it is the simplest and quickest to deploy supply chain automation is another fantastic feature.

ALSO READ

You may also like our other related articles on automation :